About IGMA in Amsterdam

IGMA, a bulk terminal in the Port of Amsterdam, is engaged in the transshipment of bulk cargo varying from agricultural products to coal and minerals.

IGMA has more than 50 years of experience. The company employs trained professionals with a great deal of know-how and knows how to process bulk products. The most advanced technologies and equipment to successfully move cargo from a ship’s hold to barges, coasters and silos is used for this purpose. Safety comes first in this respect.

Muller Beltex has worked for IGMA for many years and is jointly responsible for the installations.

The work we performed

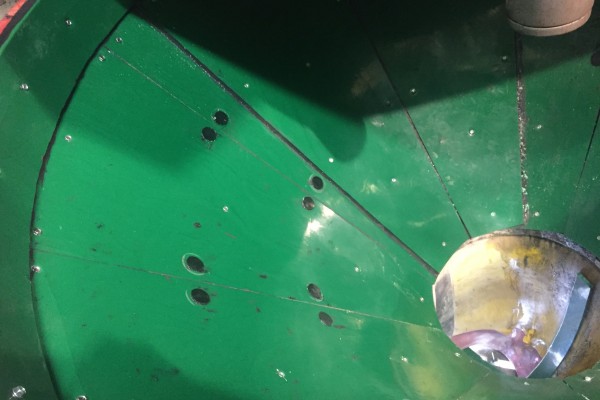

Elaborate inspections of the technical components of one of the floating weighing towers, a 36 MT Lemniscate crane with a capacity of 1500 MT/hour. The report showed that certain components required action in order to guarantee reliability; preventive and corrective maintenance.

Wear on the back of the bucket elevator belt was observed making the belt’s replacement a necessity. This was also true for the rubber pulley lagging of both drive pulleys. The crowning of the return pulleys, which was too much, exerted unnecessarily high forces and friction on the belt, as well as on the belt fastener and elevator buckets.

By preparing a suitable and thorough action plan, with a realistic time span for implementing the inspection report’s recommendations, it was decided to carry out the various activities in a single efficient stop.

The existing belts and both drive pulleys were hoisted to the lower deck using a telescopic crane. The pulleys were already equipped with Slide-Lag replaceable pulley lagging making it easy to replace them with new Slide-Lag rubber pads.

While this work was underway, a second shift started work on dismounting the return pulleys that were then machined down to reduce the crowning.

Once the newly lined drive pulleys were remounted, the new elevator belt was hoisted. At Muller Beltex the belt was provided with the right bolt hole pattern directly in the belt shop and one side of the belt was prepared to accept the belt fastener.

To enhance the belt’s durability, the new Maxi-Super elevator belt fastener was installed. This belt fastener is equipped with a replaceable rubber wear part that provides optimal support to the drive pulley, the belt and the fastener. The radius of the Maxi-Super elevator belt fastener has been designed for accepting the 1250N/mm elevator belt, securing that the belt ends will not bend off to drastically, resulting in stress on

this section of the belt.

The removal of the drive-/return pulleys provided an opportunity to replace the bearings in all housings with new bearings at the same time!

Once the return pulleys were reinstalled, the belts were made endless and adjusted to the right tension. The old elevator buckets were installed on the new belt, after which trial runs were conducted. When the weighing tower was re-commissioned, the installation was found to run more smoothly and quieter than before.

If you would like more information about this project or if you would like to know how we can help you, contact one of our specialists. They are happy to provide you with additional information.