-

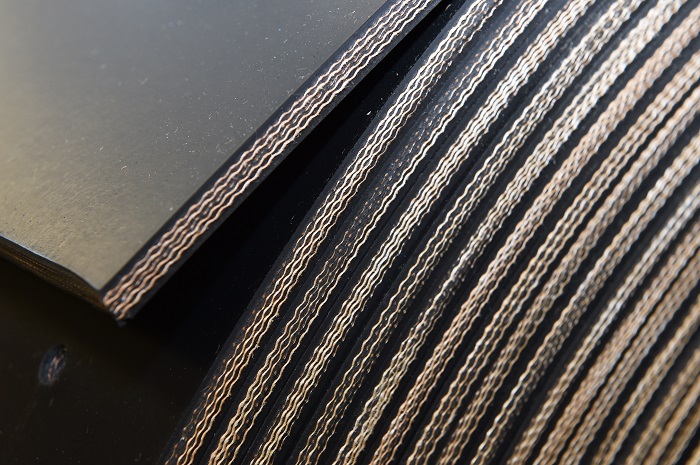

Elevator belts

Elevator beltsFrom experience we know which elevator components and moving parts are subjected to the most wear. What lies at the heart of optimal and safe bulk processing is the elevator belt: to us, the elevator belt is the key. A good quality elevator belt is crucial and can be offered with Polysur.

Elevator belts -

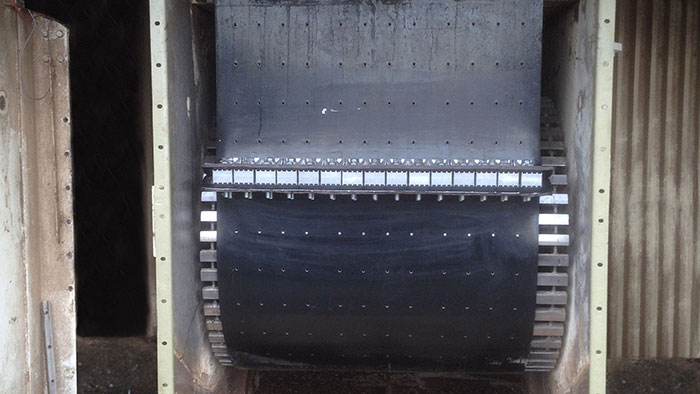

Elevator belt fasteners

Elevator belt fastenersThe connection is the weakers link in an elevator belt, which is why belt fasteners deserve special attention. We supply various belt fasteners for connecting belts with specially woven polyester/polyamide plies (EP) or steel fabric reinforcements.

Elevator belt fasteners -

Elevator buckets

Elevator bucketsWe have an extensive product range of elevator buckets for light, medium and heavy circumstances so we can always offer a fitting solution.

Elevator buckets -

Elevator bolts

Elevator boltsElevator buckets are fitted using specially designed fastening hardware.

Elevator bolts -

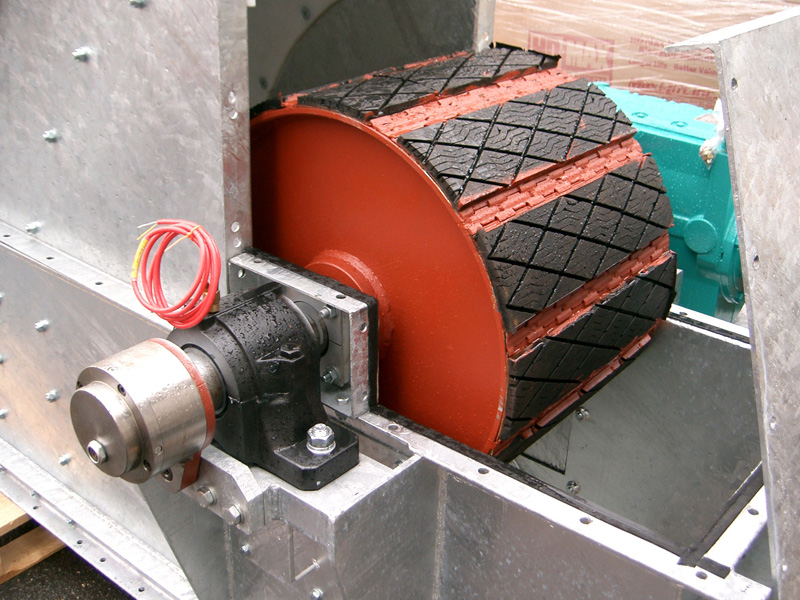

Drive and return pulleys

Drive and return pulleysFrom drive pulleys and cage pulleys to wing pulleys: our engineers take care of the entire process, from drawings to implementation providing the right solution for your elevator belt.

Drive and return pulleys -

Pulley lagging

Pulley laggingA good pulley lagging is absolutely essential for friction between the elevator belt and the drive pulley. A good lagging prevents the elevator belt from slipping and reduces wear.

Pulley lagging

A good pulley lagging is absolutely essential for friction between the elevator belt and the drive pulley. A good lagging prevents the elevator belt from slipping and reduces wear. Muller Beltex offers various possibilities.

PULLEY LAGGING

A pulley lagging that is easy to replace, like Slide-Lag, is welded onto the surface of the drive pulley, or rubber with a diamond profile is bonded to the surface using a vulcanisation process. The rubber version is also available in food-grade quality and comes in white or blue. If a rubber pulley lagging does not suffice, for instance at very high temperatures, we apply METALLAG steel segments with a ceramic or sintered nickel plating.

OVERVIEW COMPONENTS FOR ELEVATORS

Our stockholding strategy and top-quality product range allows us to always offer the right solution for your elevator. Largely the result of our customers’ needs we have continuously been optimising our product range.

OUR OTHER COMPONENTS

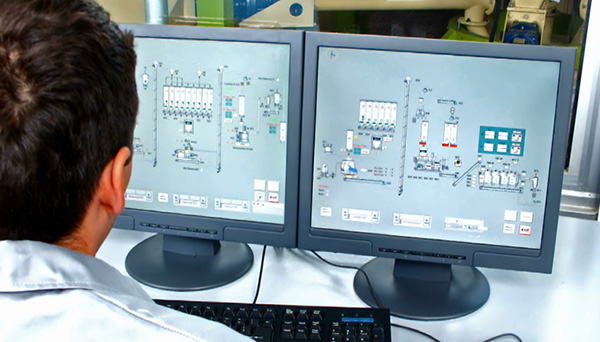

WE ALSO OFFER ENGINEERING, ADVICE AND SUPERVISION SERVICES

Muller Beltex likes to share their knowledge as a consultant for your specific issue. Engineering, advice and supervision services to get your bulk handling and processing equipment running optimally. By involving us at an early stage, we can offer you the right solution based on our broad experience and know-how.