-

Belt misalignment monitoring

Belt misalignment monitoringWith a 30 till 40% share of all company dust explosions, it’s easy to say that a bucket elevator is a dangerous installation with a real explosion risk. This can easily be prevented and damage can be limited with our range of belt misalignment systems for vertical and horizontal transportation at conveyor belts.

Belt misalignment monitoring -

Bearing temperature monitoring

Bearing temperature monitoring60% of the early malfunctioning bearings is caused by material fatigue as a consequence of continuous fluctuating pressures on the bearing its surface and the use of incorrect lubricants. Bearing monitoring sensors are able to detect damages in an early stage and prevent downtime and potential dust explosions.

Bearing temperature monitoring -

Speed monitoring

Speed monitoringTo detect belt slip in an early stage we offer several speed monitoring switches to make sure you are informed in time when the belt slips. They also safeguard applications from overspeed or underspeed.

Speed monitoring -

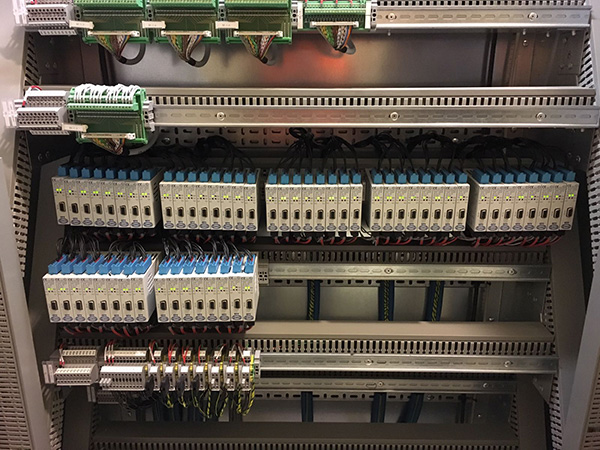

Controllers, indicators & transmitters

Controllers, indicators & transmittersFor a various range of process monitoring sensors Muller Beltex offers you the opportunity to select the correct controllers (ATEX), indicators and transmitters.

Controllers, indicators & transmitters -

Radar & level instruments

Radar & level instrumentsRadar and level instruments are generally used for cost efficient visualised level measurement of bulk goods. It supplies a continuous flow of reliable measuring data about the levels of the bulk goods in silo’s and small containers.

Radar & level instruments -

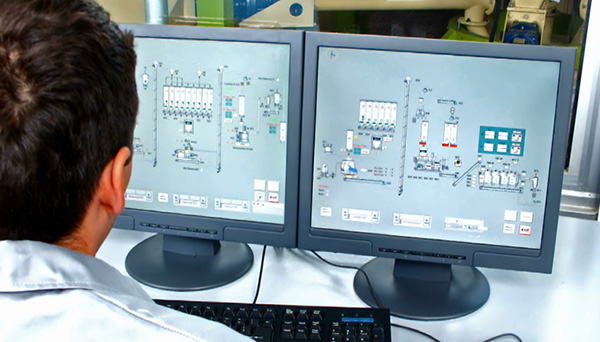

Data acquisition & SCADA systems

Data acquisition & SCADA systemsSupervisory Control And Data Acquisition, is collecting, forwarding, processing and the visualisation of monitoring signals of a various range of machines in huge industrial systems. We offer various solutions.

Data acquisition & SCADA systems -

Explosion vent panels & flameless vents

Explosion vent panels & flameless ventsExplosion pressure relief is the most natural version of constructive explosion protection. The over-pressure is deflated directly to prevent the protected amount of volume by damage of the pressure wave.

Explosion vent panels & flameless vents

Explosion pressure relief is the most natural version of constructive explosion protection. The over-pressure is deflated directly to prevent the protected amount of volume by damage of the pressure wave. When this isn’t a possibility, flameless pressure venting is a solution.

EXPLOSION VENT PANELS & FLAMELESS VENT PANELS

Explosion pressure relief is the most natural version of constructive explosion protection. The over-pressure is deflated directly to prevent the protected amount of volume by damage of the pressure wave. Depending on the situation, there are multiple possibilities such as vent panels, flameless venting and venting solutions for frequent use. You can also apply venting in workshops by the means of venting channels to release the overpressure/flames outside. When this isn’t a possibility, flameless pressure venting is a solution. Explosion technical disconnecting is a add-on according current guidelines. With these solutions you release the explosion pressure quick and correct and you prevent expansion at connected parts. Involve us at an early stage for finding the right solution for your specific issue.

OVERVIEW ATEX PROCESS MONITORING SYSTEMS

Our stockholding strategy and top-quality product range allows us to always offer the right solution for your installation, anywhere in the world. Together with an comprehensive problem analysis and the right measures and design. Flexible & fast. Largely the result of our customers’ needs we have continuously been optimising our product range.

OUR OTHER COMPONENTS

WE ALSO OFFER ENGINEERING, ADVICE AND SUPERVISION SERVICES

Muller Beltex likes to share their knowledge as a consultant for your specific issue. Engineering, advice and supervision services to get your bulk handling and processing equipment running optimally. By involving us at an early stage, we can offer you the right solution based on our broad experience and know-how.