-

1. Components for elevators

1. Components for elevatorsMuller Beltex’s elevator components are already a household name on the market and stand for quality, operational reliability and innovation. Our solutions improve efficiency.

1. Components for elevators -

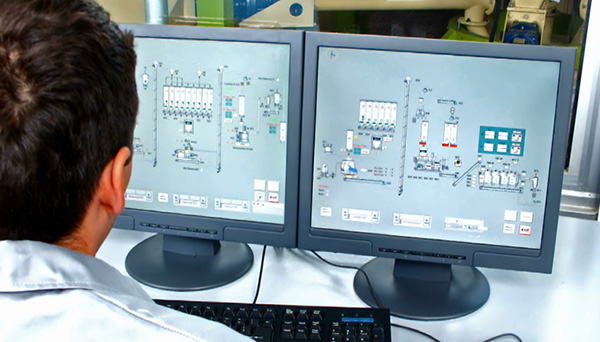

2. Process monitoring systems (ATEX)

2. Process monitoring systems (ATEX)Monitoring your production process is essential in reducing maintenance cost and to guarantee safety of man and environment. Our ATEX monitoring systems are your ensurance.

2. Process monitoring systems (ATEX) -

3. Abrasion-resistant polyurethane liners

3. Abrasion-resistant polyurethane linersMuller Beltex’s widely applicable liners are unsurpassed for its extremely high-elasticity and abrasion resistance and therefore extends the service life of your steel parts of your installation.

3. Abrasion-resistant polyurethane liners -

4. Components for horizontal conveying

4. Components for horizontal conveyingThe product range includes a wide variety of reliable components for horizontal conveying that optimize the safety and service life of your conveyor and reduce spillage.

4. Components for horizontal conveying -

5. Parts for sifters and screens

5. Parts for sifters and screensOur high-quality parts for sifters and screens contribute to an uninterrupted sifting process and minimise maintenance. Its therefore intended part meets the most stringent requirements in the food processing and chemical industries, ensuring optimal production.

5. Parts for sifters and screens -

6. Engineering, advice and supervision

6. Engineering, advice and supervisionWith our specialists and acquired broad experience and know-how we are involved at an early stage to ensure the right solution is offered for your issue. We can advise you, help you with engineering questions or even provide supervision on-site.

6. Engineering, advice and supervision

Our specialists have extensive knowledge and field experience and are involved at an early stage to provide the right solution for you issue. Not only do we supply the best components, by carefully observing each situation, we also secure the mechanical side of your installation. With engineering, advice and supervision we support you wherever needed, from plan to completion. Advise for upgrading your existing belt conveyor and bucket elevators or how to build new ones.

ADVISE AND MAINTENANCE

Also after completion we service you with a long-term plan for maintenance. To make sure continuity is maintained. We not only unburden you, we often ensure there is a capacity increase or a cost reduction per tonne of processed product too.

ON-SITE

SUPERVISION

Understandably, you expect a competent installation of your purchased components. When your company has an own technical service department we can offer on-site supervision to support and guide your employees during the fitting process, so a proper installation is secured.

ENGINEERING AND SUPPORT

We gladly advise you on your technical issue and perform capacity calculations and recommendations about upgrading existing elevators or the build of new ones.

Advise and recommendations can also be given about your existing belt conveyors or other bulk transport issues. These are just a few options in our range of possibilities.

MULLER BELTEX ACADEMY

Our “Academy” is a knowledge and workshop institute where we invite our business friends for discussion, training and exchange of knowledge. From theory and practice. The purpose is the joint enhancement of knowledge and transfer of expertise to maximise the potential of your plant and create a safe and durable workplace. Workshops on how elevators work, the application of process monitoring (ATEX) and abrasion-resistant liners and making elevator belts endless are among the available options. Interested? Contact us.