ACCESSORIES

Our product range of conveyors and components includes a wide variety of reliable components that contribute to the safety, cleanliness and lifespan of your conveyor. Muller Beltex offers conveyor belts in several qualities, as well as belt scrapers, impact bars, complete idler sets, bottom rollers, canopies, drive and idler pulleys and drum coatings.

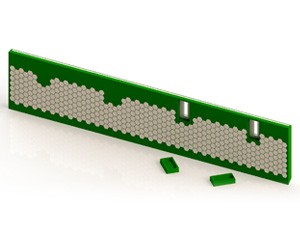

LOAD ZONE CONTAINMENT SKIRTING

Load Zone Containment Skirting

The critical component in any conveyor transfer point is an effective sealing system. The seal should be located where the material is being loaded and continue to where it becomes stable. This is the last position to practically control spillage and dust. To enhance the success of the outer seal or skirting, the loading area should be properly supported. MB-Containment Seal is a high performance, low friction engineered polyurethane system offering exceptional resistance to wear. The slotted arrangement allows for installation adjustment, ensuring that material cannot be entrapped leading to premature belt damage. In many cases the outer flexible seal is ineffective in controlling spillage as an unsupported belt trying to contain the full weight of material load would be inadequate. Instead, to effectively contain bulk material the lightweight MB-Containment Seal should be installed inside the chute to handle high internal chute pressure and therefore reduce the load on the skirting seal. The steel-backed polyurethane seal can be supplied beveled or straight edged.

DRUMS, COATING, ROLLS AND IDLER SETS

Muller Beltex provides a full line of essential accessories for belt conveyors including impact bars, side seals, idler sets, bottom rollers, canopies, drive and idler pulleys and drum coatings.

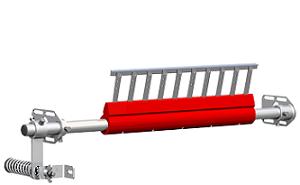

VARIOUS BELT SCRAPERS

Muller Beltex offers a complete range of primary and secondary belt scrapers. Besides complete belt scraper constructions, we also supply components such as replacement blades in steel or polyurethane.

BRUSH CLEANER

The Brush Cleaner is a completely contained system, which utilizes a Van der Graaf drum motor. This motor is an enclosed unit with all motorized parts inside the roller, making it the choice for the most challenging environments. The compact, low-profile design of this conveyor belt cleaning system provides space savings and is ideal for use on chevron belts. The system virtually requires no maintenance when operating.

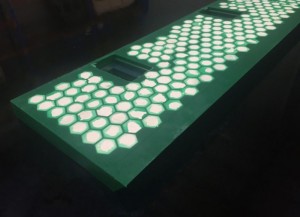

KRYPTANE KS03 DUO

OUR OTHER COMPONENTS

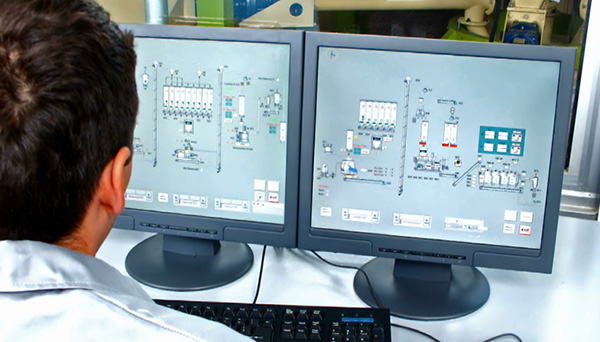

WE ALSO OFFER ENGINEERING, ADVICE AND SUPERVISION SERVICES

Muller Beltex likes to share their knowledge as a consultant for your specific issue. Engineering, advice and supervision services to get your bulk handling and processing equipment running optimally. By involving us at an early stage, we can offer you the right solution based on our broad experience and know-how.